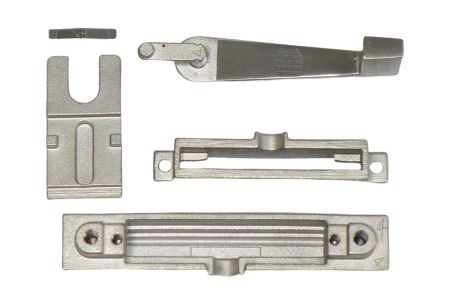

Precision Multi-Point Latch Door Hardware

Stainless Steel Multi-Point Latch Hardware

Boomster is a trusted OEM supplier specializing in custom stainless steel casting and precision machining for multi-point latch door hardware. Our one-stop OEM solution ensures high-strength, corrosion-resistant, and precisely engineered components that enhance security and functionality across various industries.

Why Choose Boomster?

- End-to-End OEM Service – From casting to final assembly, ensuring cost-effective and efficient production.

- Strict Quality Control – ISO-certified with comprehensive inspection processes to guarantee consistency and reliability.

- Flexible Production – We support low to high-volume manufacturing, adapting to your specific needs.

Key Features & Benefits:

- Premium Stainless Steel Construction – Made from high-grade stainless steel, offering superior corrosion resistance, strength, and durability.

- Precision Casting & Machining – Utilizing investment casting and CNC machining to achieve tight tolerances and intricate designs.

- Enhanced Surface Treatment – Sandblasting, brushed finish, and nitric acid cleaning for superior aesthetics and longevity.

- Reliable Performance – Designed for high-frequency operation and secure locking mechanisms, ensuring long-lasting functionality.

- Fully Customizable OEM Solution – Boomster provides mold development, casting, machining, assembly, and surface finishing based on customer designs and specifications.

Applications

- High-Security Residential Doors – Reinforced latching systems for better safety and durability.

- Commercial & Industrial Doors – Secure access control solutions for warehouses, factories, and office buildings.

- Automotive & Transportation – Heavy-duty latches for specialized vehicle doors.

- Marine & Aerospace Equipment – Corrosion-resistant components for extreme environments.

Secure Your Doors with Precision Multi-Point Latch Hardware!

Partner with Boomster for high-quality stainless steel casting and machining. Contact us today for custom OEM solutions tailored to your requirements!

Request a Quote Now!

Reliable OEM Parts Solutions

Boomster brings 37+ years of one-stop OEM expertise in metal, plastic parts, CNC, forging, casting, molding, wiring, and assembly with ISO-certified quality.

One-stop OEM service

Complete OEM services from material sourcing, fabrication, custom finish, assembly, package, and global delivery.

ISO-Certified OEM Solutions

Reliable Taiwan OEM for metal, plastic, and electronic parts with ISO 9001 certified quality assurance.

Quality You Can Trust

ISO 9001 certified, Boomster delivers strict quality control with inspection reports traceable for 3 years or longer.

Tags

Precision Multi-Point Latch Door Hardware | Boomster

Boomster specializes in precision Precision Multi-Point Latch Door Hardware with CNC machined components designed for demanding applications where accuracy and reliability are critical. Our machining capabilities cover diameters from 0.5mm to 65mm and lengths up to 1,000mm, delivering tolerances as tight as ±0.005mm in diameter and ±0.01mm in length.

Each CNC machined part is produced using advanced equipment and controlled processes, including turning, milling, boring, drilling, threading, slotting, and polishing. We work with a broad range of metals and plastics to match your functional requirements, from lightweight aerospace parts to robust automotive and medical components.

To support your quality and compliance needs, Boomster provides full inspection reports, FAI, in-process checks, and documentation such as PPAP and SGS upon request. Whether you require low-volume prototypes or stable mass production, our CNC machined components help you reduce risk, shorten development cycles, and maintain consistent performance in end-use applications.