Boomster Inspection Equipment

Boomster OEM Quality Inspection Capabilities

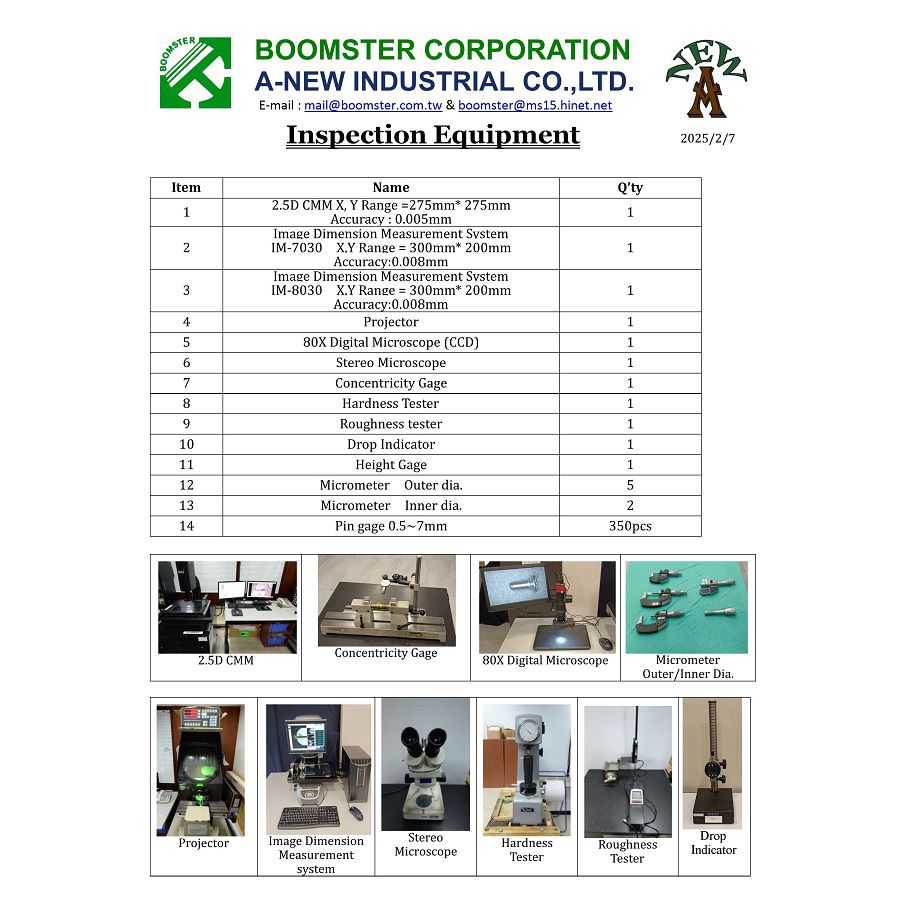

Boomster ensures consistent quality with advanced inspection equipment. Our in-house tools include CMM, 2D projectors, hardness testers, surface roughness testers, pin/thread gauges, and more. Certified to ISO 9001:2015, we provide full inspection reports, FAI, and in-process checks. From plastic to metal parts, our QC system supports automotive, medical, and electronics industries with precision and reliability.

I. Systematic Quality Planning & Supplier Audits

We establish clear quality procedures from the start and conduct regular audits with our suppliers to ensure all processes align with customer specifications. By enforcing a "right the first time" approach, we reduce defects and ensure production consistency.

II. Robust Q.C./Q.A. Execution

Our quality control and assurance system is built for reliability. Every shipment undergoes dual inspections—covering in-process and final product checks—to guarantee full compliance. All critical processes follow documented Q.C. steps without exception, ensuring traceability and long-term quality control integrity.

Reliable OEM Parts Solutions

Boomster brings 37+ years of one-stop OEM expertise in metal, plastic parts, CNC, forging, casting, molding, wiring, and assembly with ISO-certified quality.

One-stop OEM service

Complete OEM services from material sourcing, fabrication, custom finish, assembly, package, and global delivery.

ISO-Certified OEM Solutions

Reliable Taiwan OEM for metal, plastic, and electronic parts with ISO 9001 certified quality assurance.

Quality You Can Trust

ISO 9001 certified, Boomster delivers strict quality control with inspection reports traceable for 3 years or longer.

Boomster Inspection Equipment - High-Tolerance OEM Components | Boomster

Boomster is a Taiwan-based OEM manufacturer with over three decades of experience in precision metal and plastic components. Since 1987, we have provided end-to-end solutions that include tooling design, material sourcing, CNC machining, forging, metal injection molding (MIM), stamping, casting, wire harness, and turnkey sub-assembly.

Certified to ISO 9001:2015, Boomster implements strict quality control using CMM, 2D projectors, hardness testers, surface roughness testers, and various gauges to ensure every part meets your specifications. We also support your compliance requirements with documentation such as PPAP, FAI, and SGS reports, making us a reliable partner for automotive, medical, electronics, and industrial applications.

With multilingual support, flexible production volumes, and efficient shipment consolidation, Boomster helps global buyers reduce procurement complexity and total cost. Our team focuses on responsive communication, engineering collaboration, and long-term partnerships, enabling you to develop competitive products with stable quality and on-time delivery.