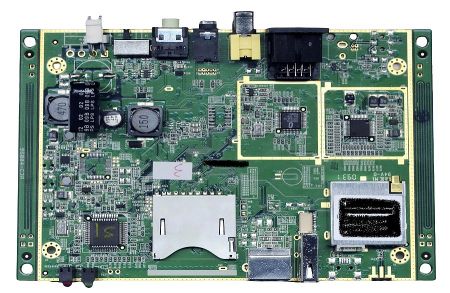

PCB Assembly

Expert PCB Assembly for Reliable Electronics

At Boomster, we specialize in comprehensive PCB Assembly services, transforming bare circuit boards into fully functional electronic modules. Our expertise extends beyond mere component placement; we provide integrated manufacturing solutions that streamline your production and ensure high-quality, reliable electronic products. By leveraging our deep understanding of advanced SMT (Surface Mount Technology) and THT (Through-Hole Technology) processes, coupled with rigorous quality control, we deliver ready-to-integrate PCBs, optimizing your product development from initial design to final packaging.

By integrating PCB Assembly into our broader manufacturing capabilities, Boomster offers customers a turnkey solution—reducing vendor management complexity and ensuring faster product cycles. Our facilities are equipped to handle both low- and high-volume production with traceable processes and IPC-compliant standards, making us a reliable partner across diverse industries.

The Boomster Advantage in PCB Assembly

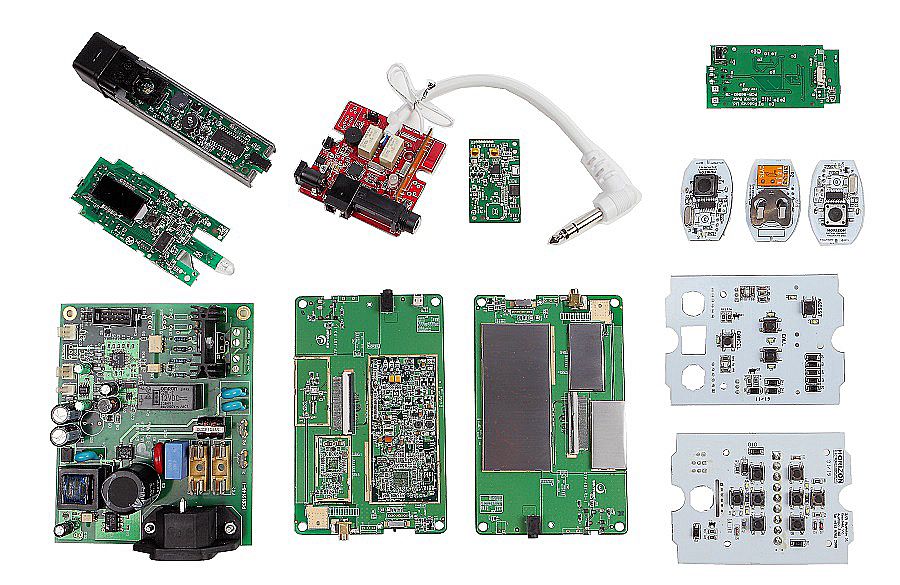

- Comprehensive Process Integration: From component sourcing to complete board assembly, we manage every step to ensure consistency and performance.

- Flexible Production Models: We support everything from engineering prototypes to mass production runs with equal precision.

- Automated & Manual Assembly: Our combination of automated SMT lines and skilled manual assembly ensures flexibility across complex PCBA builds.

- In-Process Testing & Inspection: We conduct AOI, ICT, and functional tests to verify quality and functionality at every stage.

- Supply Chain Simplification: With PCBA and sub-assembly under one roof, customers benefit from shorter lead times and fewer coordination points.

Applications for Boomster PCB Assembly:

• Consumer Electronics

• Industrial Control Systems

• Medical Diagnostic Equipment

• Automotive Electronics

• Telecommunications Devices

Accelerate development and enhance reliability with Boomster’s professional PCB Assembly services.

Reach out today to learn how we can support your electronic manufacturing needs with precision, speed, and quality assurance.

Reliable OEM Parts Solutions

Boomster brings 37+ years of one-stop OEM expertise in metal, plastic parts, CNC, forging, casting, molding, wiring, and assembly with ISO-certified quality.

One-stop OEM service

Complete OEM services from material sourcing, fabrication, custom finish, assembly, package, and global delivery.

ISO-Certified OEM Solutions

Reliable Taiwan OEM for metal, plastic, and electronic parts with ISO 9001 certified quality assurance.

Quality You Can Trust

ISO 9001 certified, Boomster delivers strict quality control with inspection reports traceable for 3 years or longer.

PCB Assembly - High-Tolerance OEM Components | Boomster

Boomster delivers high-precision PCB Assembly CNC machining services from Taiwan, specializing in both metal and plastic components for global OEM buyers. With advanced turning, milling, drilling, and multi-axis capabilities, we support everything from simple parts to complex, tight-tolerance geometries.

Backed by ISO 9001:2015 certification and AQL-based quality control, Boomster ensures every CNC machined part meets your drawing, material, and performance requirements. We handle a wide range of materials, including stainless steel, alloy steel, aluminum, brass, and engineering plastics such as POM and PEEK.

From prototypes to mass production, Boomster offers flexible batch sizes, efficient lead times, and consolidated shipments to help you streamline your supply chain. Our team supports engineers and purchasers with clear communication, technical suggestions, and reliable CNC machining solutions for automotive, medical, aerospace, electronics, and more.