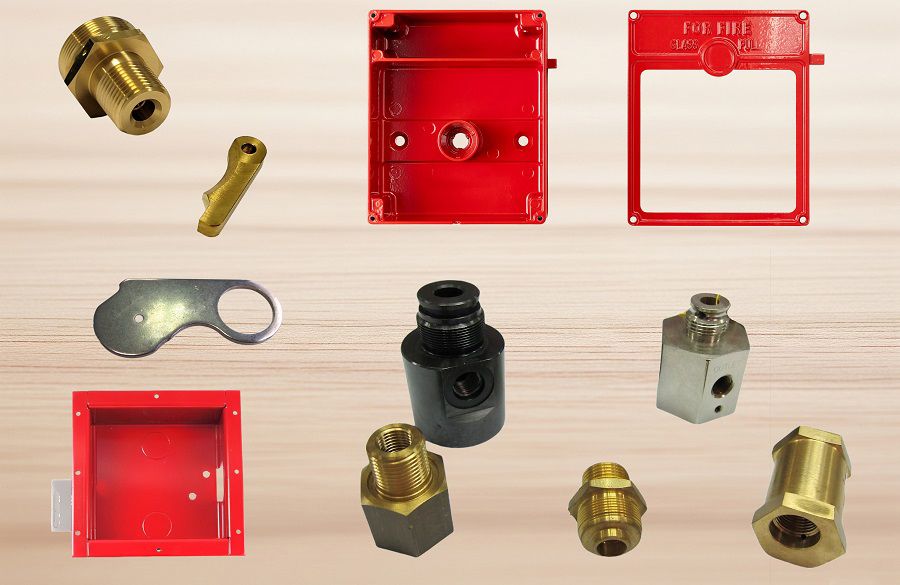

Fire Equipment Parts

Durable Hardware Solutions for Fire Safety Equipment

We understand that in the critical field of fire safety, every component must perform flawlessly under extreme conditions. Our expertise in various manufacturing processes and material enables us to produce custom solutions that meet the stringent demands for reliability, durability, and compliance within the fire protection industry.

We work with essential materials chosen for their optimal performance in fire safety applications, including corrosion resistance and high-temperature tolerance. Our comprehensive manufacturing capabilities allow us to produce a wide array of complex and robust components. Every part we produce adheres to industry standards and rigorous quality control measures, guaranteeing performance, reliability, and compliance.

The Boomster Advantage in Fire Equipment Parts Manufacturing

- Diverse Material Expertise: We skillfully process copper, aluminum, and stainless steel, tailored for fire equipment.

- Comprehensive Manufacturing Capabilities: Wide range of manufacturing methods tailored to your design

- Unwavering Quality Assurance: Rigorous checks are implemented.

- Reliable Supply Chain: Scalable production capacity with consistent lead times and quality control throughout.

Key Manufacturing Processes for Fire Equipment Parts:

• CNC Machining

• Forging

• Stamping

• Casting

• Welding

Our parts are trusted in safety-critical environments. Let’s talk today about how we can meet your quality and regulatory needs — with confidence.

Reliable OEM Parts Solutions

Boomster brings 37+ years of one-stop OEM expertise in metal, plastic parts, CNC, forging, casting, molding, wiring, and assembly with ISO-certified quality.

One-stop OEM service

Complete OEM services from material sourcing, fabrication, custom finish, assembly, package, and global delivery.

ISO-Certified OEM Solutions

Reliable Taiwan OEM for metal, plastic, and electronic parts with ISO 9001 certified quality assurance.

Quality You Can Trust

ISO 9001 certified, Boomster delivers strict quality control with inspection reports traceable for 3 years or longer.

CNC Machined Parts – Fire Equipment Parts | Boomster

Boomster delivers high-precision Fire Equipment Parts CNC machining services from Taiwan, specializing in both metal and plastic components for global OEM buyers. With advanced turning, milling, drilling, and multi-axis capabilities, we support everything from simple parts to complex, tight-tolerance geometries.

Backed by ISO 9001:2015 certification and AQL-based quality control, Boomster ensures every CNC machined part meets your drawing, material, and performance requirements. We handle a wide range of materials, including stainless steel, alloy steel, aluminum, brass, and engineering plastics such as POM and PEEK.

From prototypes to mass production, Boomster offers flexible batch sizes, efficient lead times, and consolidated shipments to help you streamline your supply chain. Our team supports engineers and purchasers with clear communication, technical suggestions, and reliable CNC machining solutions for automotive, medical, aerospace, electronics, and more.