Forging

Reliable Forged Metal Solutions

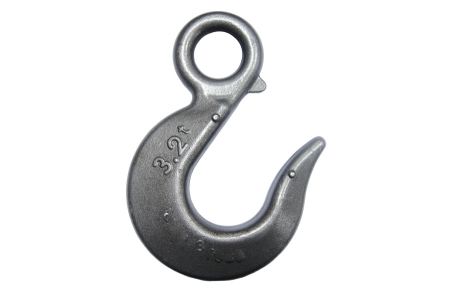

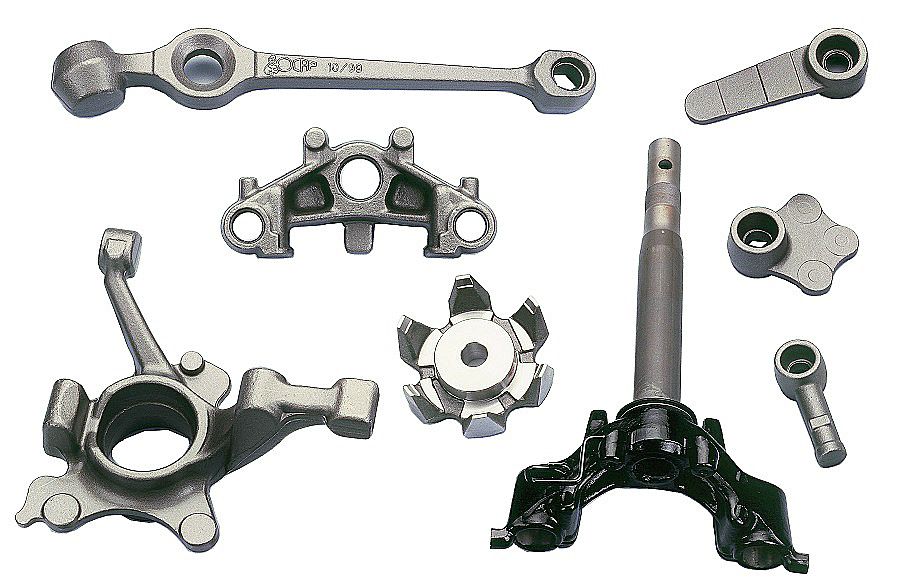

Leveraging our expertise in advanced metal forming, Boomster provides comprehensive Forging solutions and delivers durable and reliable components, precisely for your critical applications.

Whether you require components for heavy-duty equipment, safety-critical systems, or high-load environments, Boomster is your trusted partner for forging solutions that perform.

Why Choose Boomster for Your Forging Products?

- One-Stop Solution: We manage every phase of production, from material procurement to final assembly.

- Vertical Integration: Efficiently streamlining production, machining, and surface treatment under one roof.

- Rigorous Quality Control: ISO 9001:2015 certified with detailed inspection reports traceable for three years.

- Customized Solutions: Tailored logistics and packaging to meet specific project needs.

- Comprehensive Reporting: We provide material certificates, PPAP, SGS, COC, and other necessary documentation.

- Experienced Team: Over 36 years of experience in OEM solutions, ensuring quality and on-time delivery.

Industries We Serve:

• Automotive

• Heavy Duty Equipment

• Rail & Marine Equipment

• Hardware & Tools

Choose Boomster for your forging needs, to explore how our forging solutions can support your most demanding applications.

Reliable OEM Parts Solutions

Boomster brings 37+ years of one-stop OEM expertise in metal, plastic parts, CNC, forging, casting, molding, wiring, and assembly with ISO-certified quality.

One-stop OEM service

Complete OEM services from material sourcing, fabrication, custom finish, assembly, package, and global delivery.

ISO-Certified OEM Solutions

Reliable Taiwan OEM for metal, plastic, and electronic parts with ISO 9001 certified quality assurance.

Quality You Can Trust

ISO 9001 certified, Boomster delivers strict quality control with inspection reports traceable for 3 years or longer.

Forging - High-Tolerance OEM Components | Boomster

Boomster delivers high-precision Forging CNC machining services from Taiwan, specializing in both metal and plastic components for global OEM buyers. With advanced turning, milling, drilling, and multi-axis capabilities, we support everything from simple parts to complex, tight-tolerance geometries.

Backed by ISO 9001:2015 certification and AQL-based quality control, Boomster ensures every CNC machined part meets your drawing, material, and performance requirements. We handle a wide range of materials, including stainless steel, alloy steel, aluminum, brass, and engineering plastics such as POM and PEEK.

From prototypes to mass production, Boomster offers flexible batch sizes, efficient lead times, and consolidated shipments to help you streamline your supply chain. Our team supports engineers and purchasers with clear communication, technical suggestions, and reliable CNC machining solutions for automotive, medical, aerospace, electronics, and more.