OEM Turnkey Door Closer Manufacturing Solutions

End-to-End OEM Service

Boomster provides end-to-end OEM manufacturing solutions for door closers, streamlining your supply chain with precision and efficiency. With over 30 years of experience, we specialize in full-spectrum turnkey services—from product engineering and component sourcing to mechanical assembly, testing, and packaging. Our solutions are tailored for global door hardware brands, security system integrators, and commercial builders seeking ready-to-install products that meet international performance standards.

Boomster OEM Advantages

- True Turnkey Manufacturing: One partner from prototype to final shipment—sourcing, machining, and testing all handled in-house.

- ISO-Certified Quality Systems: Every unit undergoes rigorous inspection using industry-standard testing jigs and measurement protocols.

- Flexible Production Scale: Whether you require low-volume specialty closers or high-volume runs for commercial contracts, we scale efficiently without sacrificing lead time.

- Confidential & Secure: We safeguard your intellectual property through strict confidentiality agreements and secure design protocols.

Our Turnkey Service Covers:

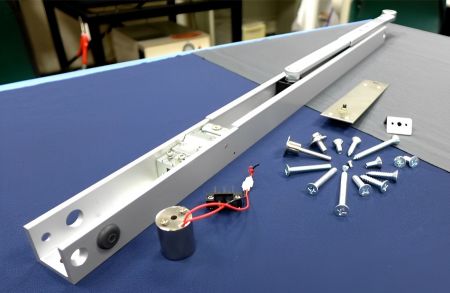

- Component Sourcing & Quality Materials - We procure high-quality hydraulic cylinders, springs, valves, arms, and cast housings from trusted suppliers to ensure product consistency and durability.

- Mechanical & Sub-Assembly Services - Boomster handles the full assembly process—press-fitted arms, sealed hydraulic chambers, adjustment screws, and end-cap integration—under strict quality control.

- Packaging & Global Delivery - We provide private-label packaging, instruction manuals, barcode labeling, and coordinated shipping logistics, delivering a retail- or project-ready solution.

Let Boomster power your next-generation door control solutions with high-quality door closers manufactured to spec and delivered turnkey—ready for installation or market.

Reliable OEM Parts Solutions

Boomster brings 37+ years of one-stop OEM expertise in metal, plastic parts, CNC, forging, casting, molding, wiring, and assembly with ISO-certified quality.

One-stop OEM service

Complete OEM services from material sourcing, fabrication, custom finish, assembly, package, and global delivery.

ISO-Certified OEM Solutions

Reliable Taiwan OEM for metal, plastic, and electronic parts with ISO 9001 certified quality assurance.

Quality You Can Trust

ISO 9001 certified, Boomster delivers strict quality control with inspection reports traceable for 3 years or longer.

Tags

OEM Turnkey Door Closer Manufacturing Solutions | Boomster

Boomster specializes in precision OEM Turnkey Door Closer Manufacturing Solutions with CNC machined components designed for demanding applications where accuracy and reliability are critical. Our machining capabilities cover diameters from 0.5mm to 65mm and lengths up to 1,000mm, delivering tolerances as tight as ±0.005mm in diameter and ±0.01mm in length.

Each CNC machined part is produced using advanced equipment and controlled processes, including turning, milling, boring, drilling, threading, slotting, and polishing. We work with a broad range of metals and plastics to match your functional requirements, from lightweight aerospace parts to robust automotive and medical components.

To support your quality and compliance needs, Boomster provides full inspection reports, FAI, in-process checks, and documentation such as PPAP and SGS upon request. Whether you require low-volume prototypes or stable mass production, our CNC machined components help you reduce risk, shorten development cycles, and maintain consistent performance in end-use applications.