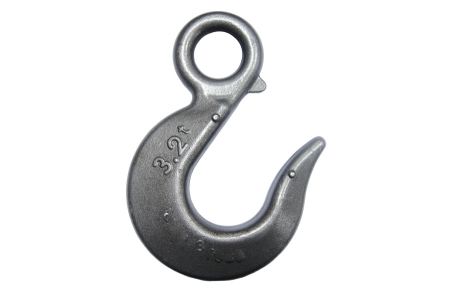

Heavy-Duty Forged Lifting Hooks

High-Tensile Alloy Forging Hook

Boomster provides OEM forging services for lifting hooks used in material handling, construction, marine, and industrial safety applications. With decades of experience in providing custom high-strength forged components, we offer precision forging solutions that meet international safety standards and customer-specific requirements.

Our forged lifting hooks are built for tough, high-load environments, ensuring both durability and reliability.

Boomster OEM Advantages

- Over 30 years of experience in forged parts for global industries

- ISO 9001:2015 certified for consistent quality control

- Full OEM support from tool design, forging, machining, to surface treatment and packing

- Capable of small-batch to mass production

- Export-ready with custom labeling and packaging solutions

- Traceable quality with material certificates and inspection reports

Key Features & Benefits:

- Forged for Strength – Produced through hot forging or closed-die forging using alloy steel or carbon steel, enhancing grain structure for superior load-bearing capacity.

- Precision Machining – Post-forging CNC machining ensures tight tolerances at critical contact and load areas.

- Customized Sizes & Load Ratings – Manufactured based on customer drawings, with adjustable designs to meet specific load capacities, shapes, and dimensions.

- Corrosion Resistance Options – Finishes include zinc plating, powder coating, black oxide, or custom coatings to extend lifespan in challenging environments.

Applications

- Construction & Rigging – Load-securing, hoisting, and lifting applications.

- Marine & Offshore – Heavy-duty hooks for marine and dock operations.

- Automotive & Transportation – Towing hooks and securing components.

- Industrial & Manufacturing – Material handling and machine lifting.

- Safety Equipment – Fall protection and industrial safety gear.

Looking for a reliable forging partner for your lifting hook designs?

Choose Boomster to ensure your components deliver strength, safety, and long-lasting performance in every lift.

Reliable OEM Parts Solutions

Boomster brings 37+ years of one-stop OEM expertise in metal, plastic parts, CNC, forging, casting, molding, wiring, and assembly with ISO-certified quality.

One-stop OEM service

Complete OEM services from material sourcing, fabrication, custom finish, assembly, package, and global delivery.

ISO-Certified OEM Solutions

Reliable Taiwan OEM for metal, plastic, and electronic parts with ISO 9001 certified quality assurance.

Quality You Can Trust

ISO 9001 certified, Boomster delivers strict quality control with inspection reports traceable for 3 years or longer.

Heavy-Duty Forged Lifting Hooks | Boomster

Boomster specializes in precision Heavy-Duty Forged Lifting Hooks with CNC machined components designed for demanding applications where accuracy and reliability are critical. Our machining capabilities cover diameters from 0.5mm to 65mm and lengths up to 1,000mm, delivering tolerances as tight as ±0.005mm in diameter and ±0.01mm in length.

Each CNC machined part is produced using advanced equipment and controlled processes, including turning, milling, boring, drilling, threading, slotting, and polishing. We work with a broad range of metals and plastics to match your functional requirements, from lightweight aerospace parts to robust automotive and medical components.

To support your quality and compliance needs, Boomster provides full inspection reports, FAI, in-process checks, and documentation such as PPAP and SGS upon request. Whether you require low-volume prototypes or stable mass production, our CNC machined components help you reduce risk, shorten development cycles, and maintain consistent performance in end-use applications.